|

composition |

Parameter |

|

Pure lead |

Pb-99.99% |

|

Lead-antimony alloy |

Sb-0.3-0.4% |

|

Lead-stannum-antimony alloy |

Sn-0.4%; Sb-0.2% |

|

Lead-antimony-copper alloy |

Sb-0.4%; Cu-0.04% |

|

Lead-stannum-cadmium alloy |

Sn-0.2%; Cd-0.075% |

|

No. |

Item |

Unit |

Qty |

|

1 |

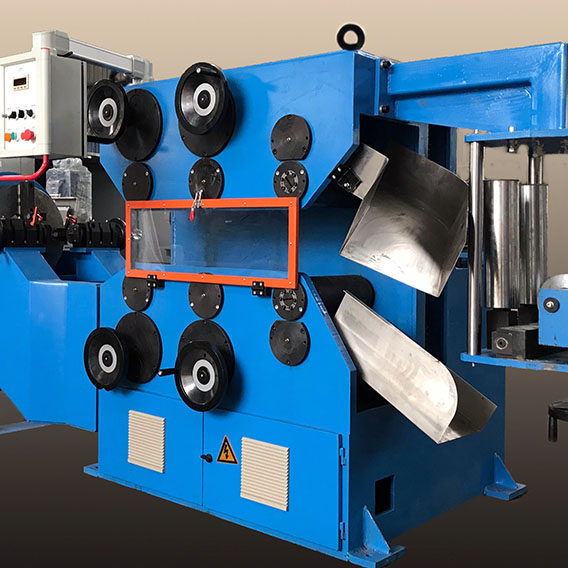

Active Loading ingot unit with rollers |

set |

1 |

|

2 |

118T melting furnace(installation in parallel ) |

set |

2 |

|

3 |

Ω pipe |

pc |

1 |

|

4 |

Host machine of ¢200/5 lead extruder |

set |

1 |

|

5 |

Gear lubricant oil system |

set |

1 |

|

6 |

Internal Water circulating & cooling system |

set |

1 |

|

7 |

Rear water cooling system |

set |

1 |

|

8 |

Vertical single guide roller frame for inlet and outlet cables |

pc |

2 |

|

9 |

Flowage control unit(shift by manual or automatic control) |

set |

1 |

|

10 |

Electrical control system |

set |

1 |

cable dia. scope Φ36~Φ152mm

Lead sheathing scope: Φ40~Φ160mm

Extruding Output:

|

Lead composition |

Screw speed (rpm) |

Extruded output (kg/min) |

|

Pure lead |

6~12rpm |

30~45Kg/min |

|

Soft alloy lead |

6~9rpm |

15~30Kg/min |

|

Hard alloy lead |

6~9rpm |

13~24kg/min |

Thickness of lead layer: 1.6~4.6mm

Lead layer tolerance: ± 0.2~0.5mm

Internal water circulating consumption: 6~8t/h