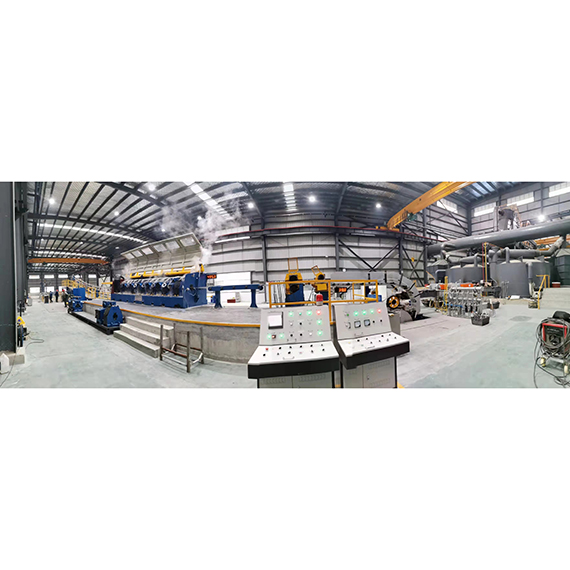

Aluminum Continuous Casting And Rolling Line

Description

This equipment uses a new type of four wheel planetary

continuous casting machine and continuous casting and rolling

process to produce conducting round aluminum rod. The

production rod diameter is 15, 12, and 9.5 millimeter. 15 racks

for 9.5mm aluminum rod, 13 racks for 12.5 mm aluminum rod, and

11 racks for 15 mm aluminum rod. The continuous rolling mill

has the function of active feeding and rod stopping, and the

outlet of takeup guide pipe is equipped with a blow drying

device to remove the surface moisture of the aluminum rod and

ensure the smooth export of the aluminum rod. The circular

guide tube adopts roller guide structure to reduce the scratch

on the aluminum rod surface. The winding rod is a centrifugal

head type, so that the aluminum bar can be pre-deformed before

entering the take-up frame. It has a trolley moving device, so

that it does not change the rod when changing the bobbin, so as

to ensure the continuous double bobbin winding device to take

up.

Brief technological process:

Melting furnace (supplied by customer)→Holding furnace(supplied by customer)→New type four wheel Continuous casting machine→Front traction→Rolling shear→Feeding→Continuous rolling machine→coiling machine→Al. rod

Melting furnace (supplied by customer)→Holding furnace(supplied by customer)→New type four wheel Continuous casting machine→Front traction→Rolling shear→Feeding→Continuous rolling machine→coiling machine→Al. rod

|

Dia. of the crystallizing wheel |

1600mmΦ |

|

Section area of the crystallizing wheel |

2400 mm2 |

|

Section of the ingot |

2380mm2² |

|

Casting speed |

7.6-15m/min |

|

Cooling water pressure of the crystallizing wheel |

0.2-0.5Mpa |

|

Cooling water temperature |

15-45℃ |

|

Cooling water requirement |

industrial water |

|

Dia of outlet rod |

¢9.5、¢12 、¢15 |

|

Rack number |

15 |

|

Max final rolling speed |

V=6.2m/s |

|

Main motor power |

280kw(DC) |

|

Output |

4——4.5T/h |

|

Product catalog |

EC1350 series |